WE STRIVE TO NOT ONLY MEET BUT EXCEED EXPECTATIONS

Quality assurance is of the utmost importance. We understand that our partners and customers rely on us to provide components that meet the highest quality standards, and we take this responsibility very seriously. That’s why we have invested heavily in our quality management capabilities to ensure that every component we supply is of the highest quality. By maintaining the highest quality standards, we are able to provide our partners and customers with components that not only meet but exceed their expectations. This can help to improve product performance, reduce costs through improved efficiency and reliability, and enhance the overall customer experience. We are committed to delivering the highest level of quality and customer satisfaction in everything we do. Whether you are looking for high-quality production components or need expert advice on a specific application, our team is here to help.

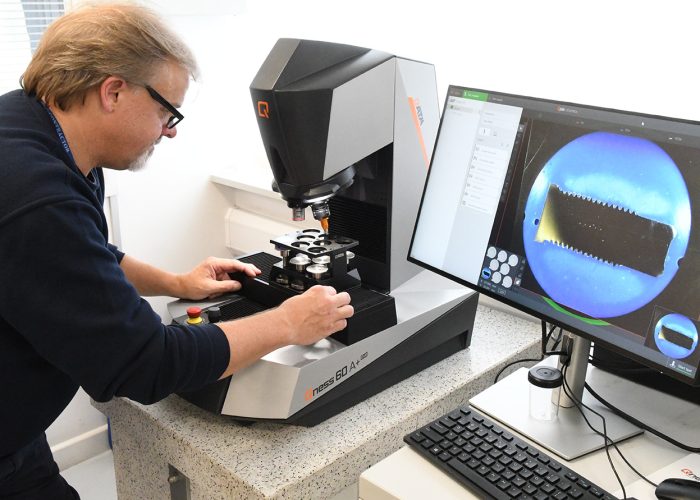

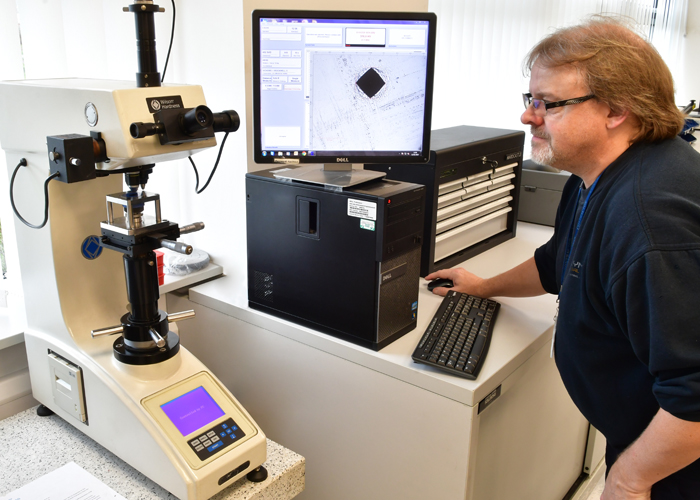

Testing Laboratory & Cutting Edge Equipment

Our experienced team utilise an extensive array of inspection equipment to perform a range of quality control checks on all components. This includes dimensional and material testing, surface finish analysis and performance testing, among others. Our quality management system together with engineering support is designed to ensure that every component meets the required specifications and performs as expected in its intended application. We are proud to offer an extensive range of on-site inspection equipment, utilised to help ensure that the highest levels of quality and performance are maintained throughout our product ranges. Our inspection equipment is highly advanced and is tailored to provide accurate, reliable results with server-based data storage systems allowing inspection records to be held in a singular, easy to access location.

Equipment

KEYENCE

IM6120 image dimension measurement system

TESA

3D manual coordinate measuring machine CMM

HEIGHT GAUGES

Height gauges Vernier callipers

& micrometers

TAYLOR HOBSON

Surtronic surface roughness tester

MECTRON

Q5000 qualifier laser sorting machines

TAYLOR HOBSON

Surtronic surface roughness tester

LK G90-C

CNC control room coordinate measuring machine (CMM)

PLUG & RING GUAGES

Thread plug & ring guages

Wilson – Tukon Vickers

Macto / micro hardness testing machines with on-site specimen preperation facility

Quality Assurance

Our quality control extends right across the manufacturing process so that we can be confident both in the integrity of our partners and in the quality that they produce. This confidence is passed onto our customers, who know that they can rely on our quality management to ensure the high manufacturing standards of the components. We have invested heavily in our quality department so whether it is a M3 machine screw or a 45kg casting, Olympus have the technology and equipment that enables us to verify product on arrival, giving our customers an extra level of confidence. Quality products need a trusted supply chain, and we will deliver. This emphasis on quality can help to improve product performance, reduce costs through improved efficiency and reliability, and enhance

the overall customer experience.

We have invested in advanced technologies to ensure that continue to meet and exceed our high standards for quality. We combined this passion for quality, with a deep understanding of the importance of a smooth and seamless supply chain for the customers that we support. As with all good engineering, we need all the parts to work together to create a good final result. We combine our quality management with our supply chain management to create a distribution service that you can rely on.

Whether you need engineering fasteners, precision turned and machined components, casting, extrusions and forgings, pressing and fabrications, or plastic and rubber parts, we can source and quality test these components for you. For quality that you can rely on, come to the team at Olympus Global.

Quality Management

We are proud to be certified to ISO 9001 and ISO 14001 standards, which are recognised worldwide as the leading international standards for quality management, environmental management, and occupational health and safety management respectively. These certifications demonstrate our commitment to maintaining the highest levels of quality, environmental responsibility, and occupational health and safety in all aspects of our business.

ISO 9001 certification ensures that our quality management system is designed to meet the needs of our customers, and that we have the necessary processes in place to ensure that all components we supply meet the required specifications. ISO 14001 certification demonstrates our commitment to environmental responsibility. By achieving these certifications, we are able to provide our partners and customers with the assurance that they are working with a company that is committed to maintaining the highest quality standards and providing a safe and healthy workplace. Olympus’ Commercial and Technical teams start the APQP process ensuring that all stated and implied requirements are achievable and that the correct supply source is identified to guarantee quality supplies.

NEW PRODUCTS – RIGHT FIRST TIME

We understand the need to achieve new product introduction approvals, on time, right first time. Our dedicated PPAP Engineering team are able to fulfil the requirements of each individual customer whether according to PPAP or ISIR submission levels.